NICOLAI NUCLEON 16 SUPRE

The Nicolai Nucleon 16 Supre an enduro bike in the 160–180mm travel category. Its high pivot suspension makes it composed in the rough stuff, but unlike many other high pivot bikes, it has high anti-squat and an efficient drivetrain which makes it great to pedal. The frame is machined and welded out of aluminum in Germany by Nicolai, and it’s equipped with the Supre Drive, made by us in Canada. The Nicolai Nucleon 16 Supre is no longer available for sale, but we’re keeping this page for those who would like to learn about this unique bike.

A pioneering high-pivot enduro bike equipped with the Supre Drive

SINGLE PIVOT, LINKAGE-DRIVEN SHOCK

The Nucleon 16 has high pivot suspension with the rear wheel pivoting around the pivot point just in front of the idler pulley. The rearward axle path creates control in the rough and the idler pulley reduces pedal kickback. The CNC machined part at the top of the shock is fixed to the front triangle. The linkage that drives the compression of the shock is at the bottom of the shock.

ROOTED IN HISTORY

There have been earlier models of the Nucleon with a gearbox and high pivot suspension. These bikes lacked derailleur problems, but like all gearbox mountain bikes, the drivetrain was heavy and inefficient. The Nucleon 16 Supre is a modern, Supre version of the Nucleon that shares the gearbox characteristic of toughness while having the advantages of derailleur drivetrains, such as low weight and high efficiency.

DURABLE

At the suspension pivots, there are O-rings seals in addition to bearings’ wiper seals. This additional sealing increases bearing life. Similarly, the pulleys of the Supre Drive have additional sealing, but because of the efficiency requirements of drivetrains, this additional sealing is achieved with labyrinth seals. The Supre Drive and Nicolai frames share a pursuit for longevity.

Equipped with the Supre Drive

- ultra durable

- efficient

- well damped

- made in Canada

Geometry

The geometry numbers of the Nucleon can be seen in the tech sheet accessible through the following button. The Nucleon 16 was available in five frame sizes from S to XXL along with the option for custom geometry.

(geometry is in the second tab)

Suspension

This suspension system is single pivot with the shock driven by a linkage.

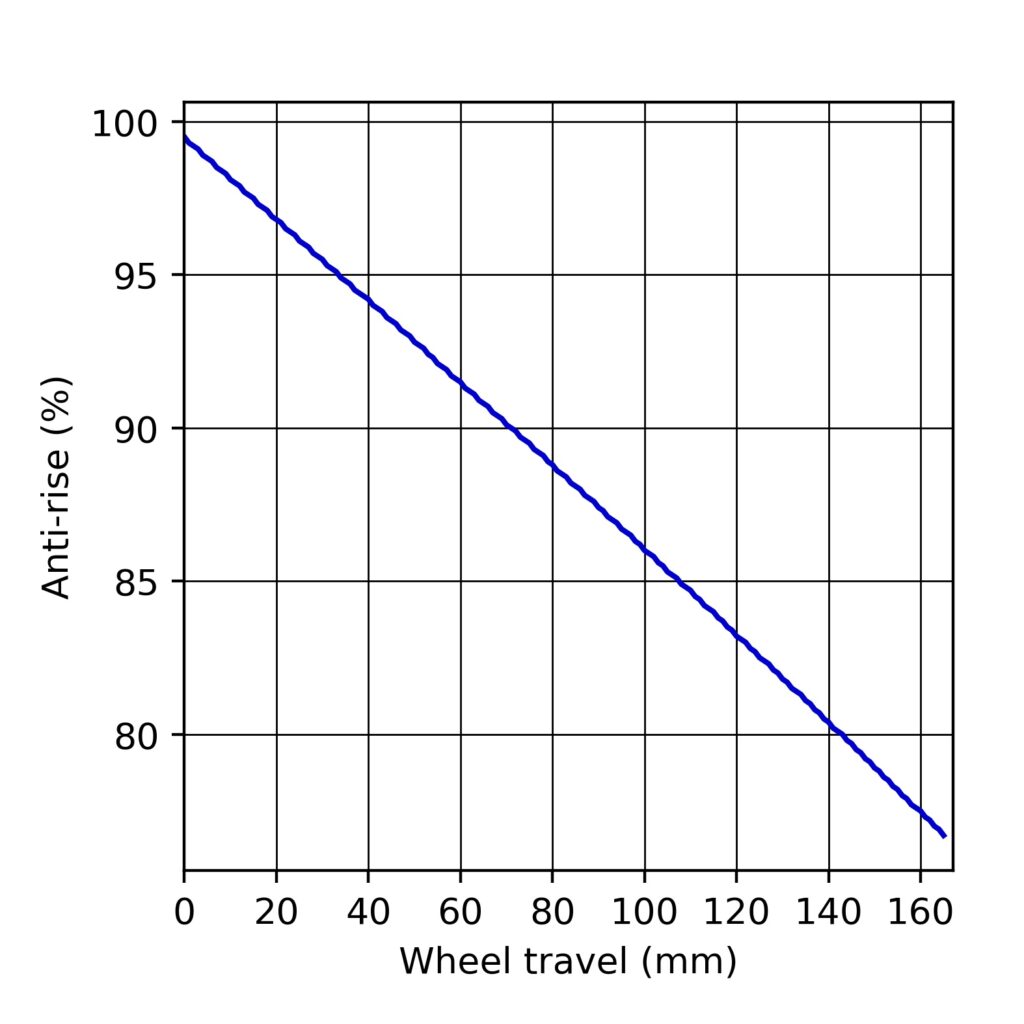

Anti-rise

Anti-squat

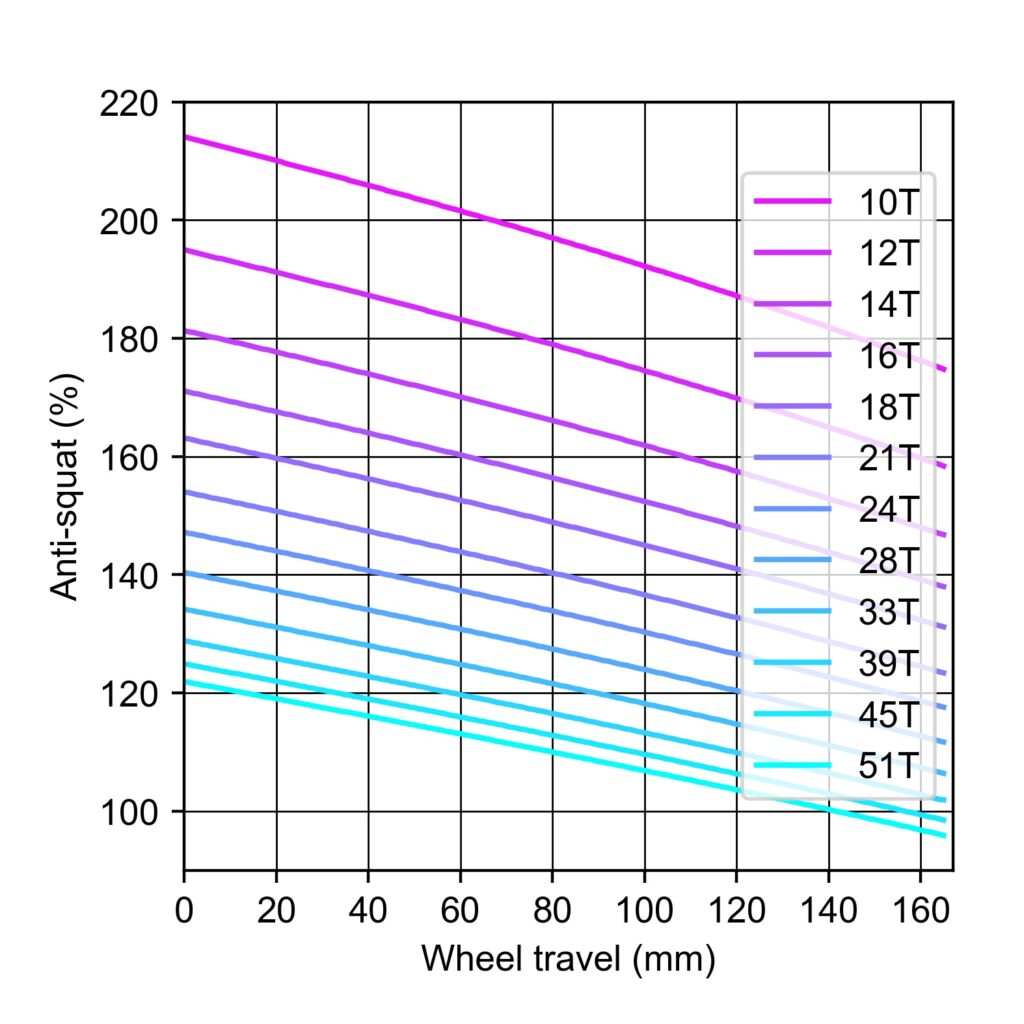

The Nucleon’s anti-squat is high and it increases toward the high gears. This may seem counter-intuitive since we pedal so much in our low gears, but it makes sense because when in low gears, riders often sit while pedalling, and when in high gears, riders often stand up while pedaling. There are additional bob-inducing forces while standing up and pedalling. For neutralizing these forces, more anti-squat is needed. Increasing anti-squat toward high gears is a characteristic that’s shared by other bikes that are known to pedal well. Overall, the Nucleon 16 has great pedalling characteristics. (The following graph assumes a center of mass height of 1100mm.)

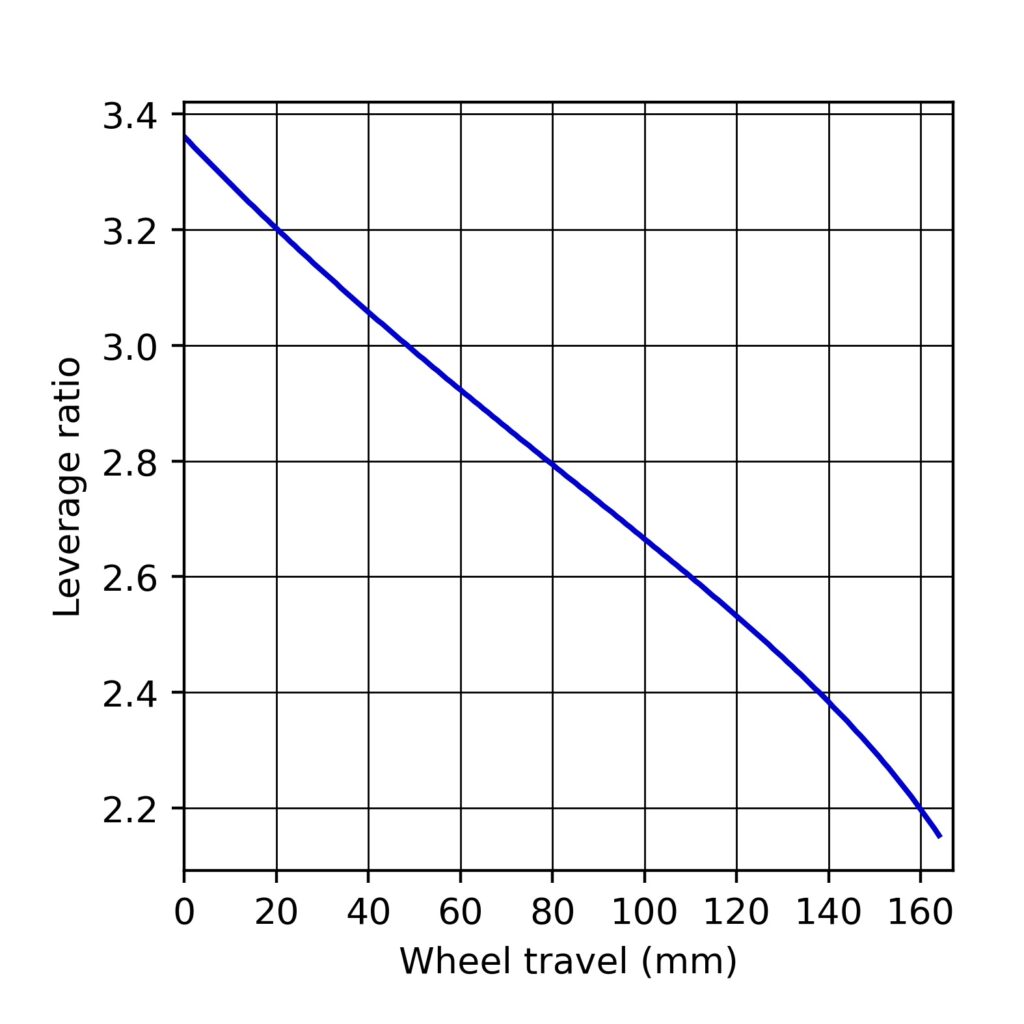

Leverage ratio

The leverage ratio is progressive. This is optimized for coil shocks or large volume air shocks. Also, the overall leverage ratio is high, which generally makes the suspension supple and lively (depending on the shock settings).

Axle path

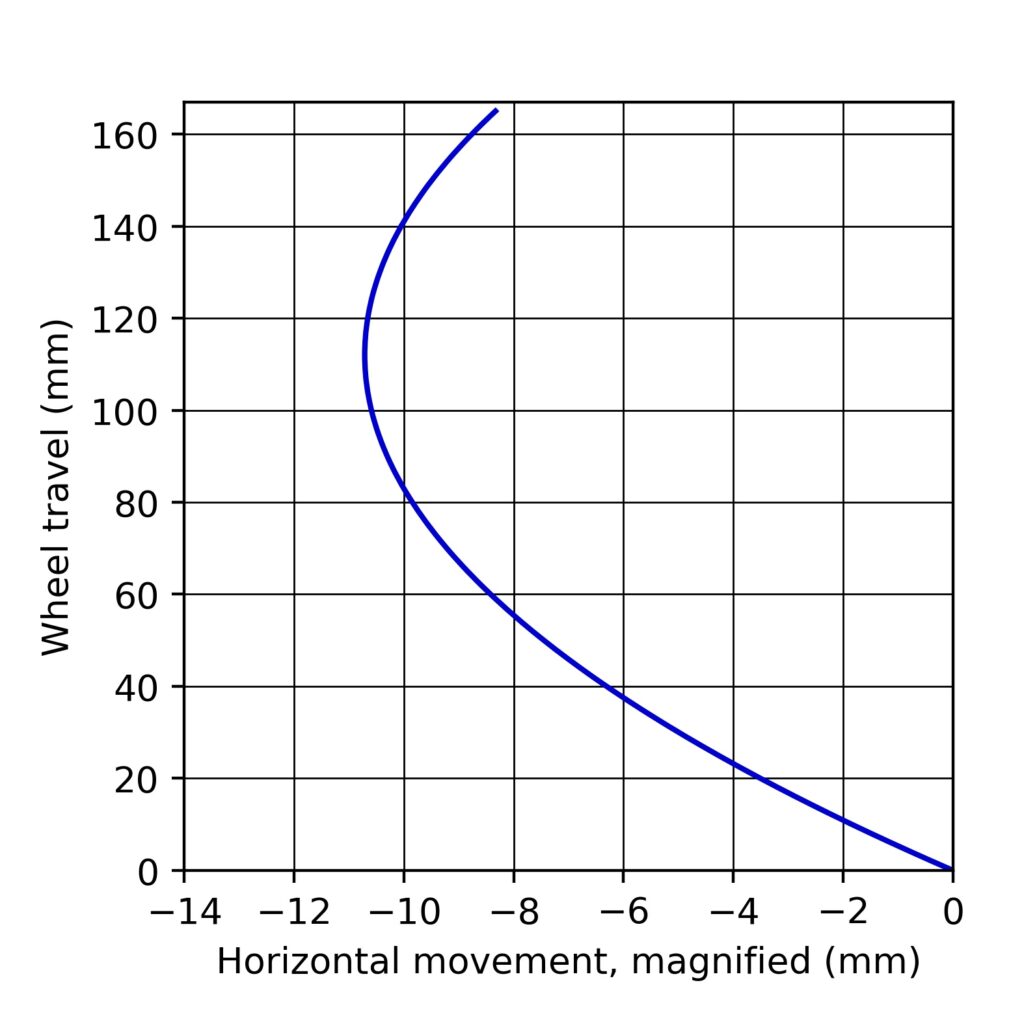

The Nucleon 16 has a rearward axle path that makes it mow over bumps and maintain momentum. The idler pulley enables this axle path, keeping pedal kickback low despite the high anti-squat. Note that the axle path graph is magnified (stretched horizontally to make the graph more useful).

a bold leap forward in mountain bike design

Nicolai Nucleon 16 Supre

North American distribution

Shipping an individual frame from Germany to North America is expensive. To reduce this cost while also providing local after-sales support, we at Lal Bikes distribute Nucleon 16 frames in Canada and the United States. Our after-sales support includes replacement parts and guidance on frame maintenance procedures, with our in-depth understanding of both the frame and drivetrain. Also, we can offer complete, custom builds with parts sourced through North American distributors. Our goal is to make ownership of a Nicolai Nucleon 16 in North America as easy and affordable as possible. Customers in Canada and the United States can order the Nucleon 16 frame and the Supre Drive through our online shop. Customers in Europe are asked to order these directly from Nicolai. If you have any questions, please don’t hesitate to contact us.